Was uns antreibt

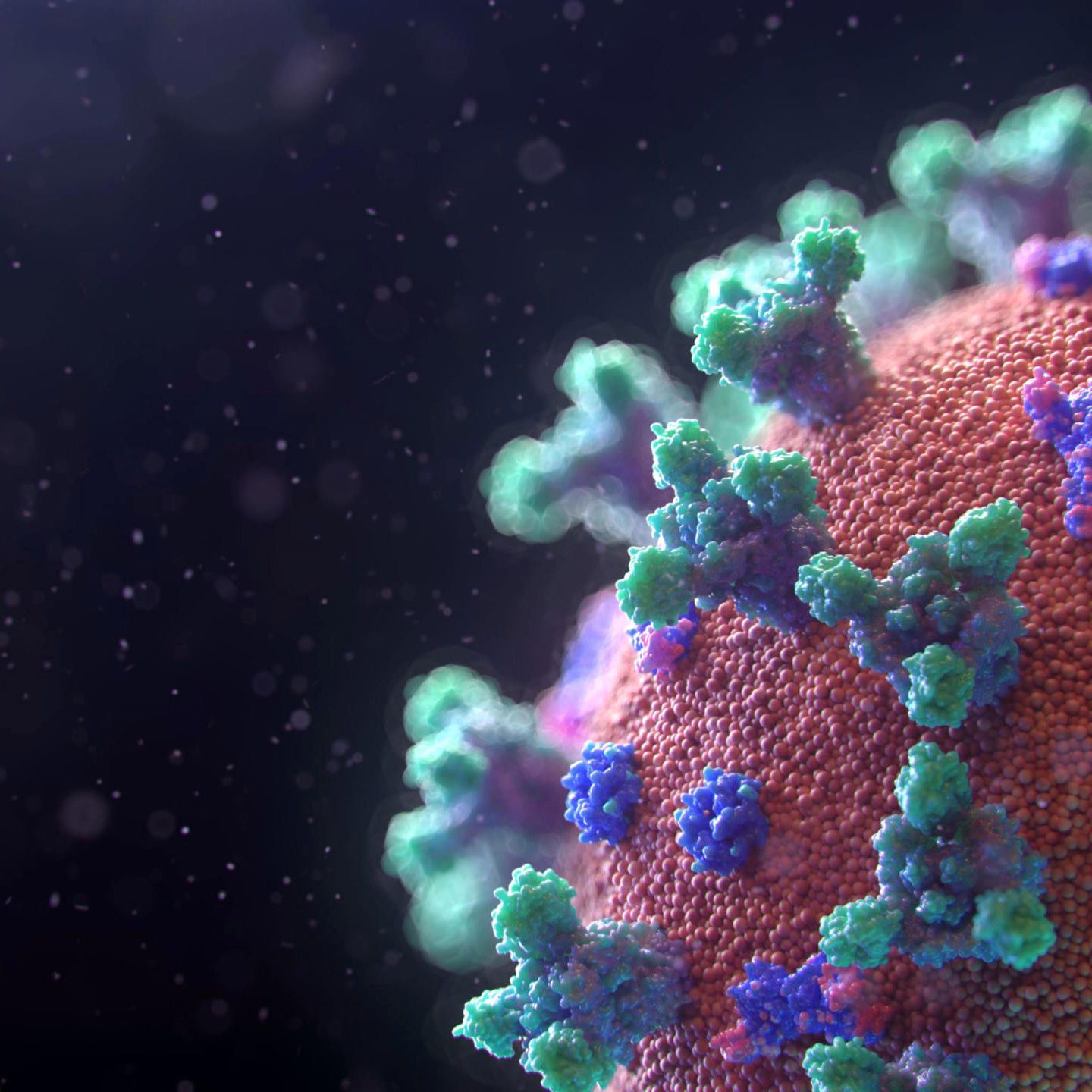

Als ein weltweit führendes biopharmazeutisches Unternehmen streben wir danach, richtungsweisende Medikamente zu entwickeln, um das Leben von Menschen zu schützen und zu verbessern. Angetrieben durch unsere RNA-Technologieplattform und zwei Jahrzehnte Exzellenz in Wissenschaft und Produktion widmen wir uns der Entwicklung neuartiger Behandlungen, die es dem Körper ermöglichen, seine eigenen prophylaktischen und therapeutischen Medikamente herzustellen.

Eilmeldung

CureVac N.V. (Nasdaq: CVAC) – (6. Mai 2022) dievini Hopp BioTech Holding GmbH & Co. KG, DH-LT-Investments GmbH und Dietmar Hopp haben zusammen mit den Geschäftsführern von dievini und den assoziierten Unternehmen eine private Transaktion durchgeführt, bei der sie Aktien von CureVac untereinander übertragen haben. Diese Transaktion folgte auf eine Ankündigung vom 22. Februar 2022, in der die Parteien offengelegt haben, dass sie einen Teil ihrer Beteiligung an CureVac nicht mehr verkaufen wollen – abgesehen von privaten Übertragungen untereinander. Die Übertragung der Anteile erfolgte im Rahmen eines Umsetzungsplans zur vollständigen Übertragung des Eigentums an die dievini Hopp BioTech Holding in die Hände der Familie Dietmar Hopp und einer Familienstiftung. Nach Abschluss der Transaktion besitzt dievini nun 86.160.390 Aktien des Unternehmens und damit rund 46 Prozent. Dietmar Hopp investierte erstmals 2005 in CureVac und ist nach wie vor ein starker Befürworter des Unternehmens und der Zukunft seiner mRNA-Technologie.

Die Transaktion wurde in einer Einreichung bei der Securities & Exchange Commission vom 5. Mai 2022 offengelegt, die hier verfügbar ist. Großaktionäre, die mindestens 5 Prozent einer CureVac-Aktie besitzen, müssen ihre Verkäufe und Käufe der SEC offenlegen.