From discovery to patent: The CureVac way

CureVac is truly a one-stop shop for mRNA therapeutics, encompassing every step along the R&D journey, from discovery to production. Our high standards for discovery and production have led to high returns—we currently have approximately 800 granted patents.

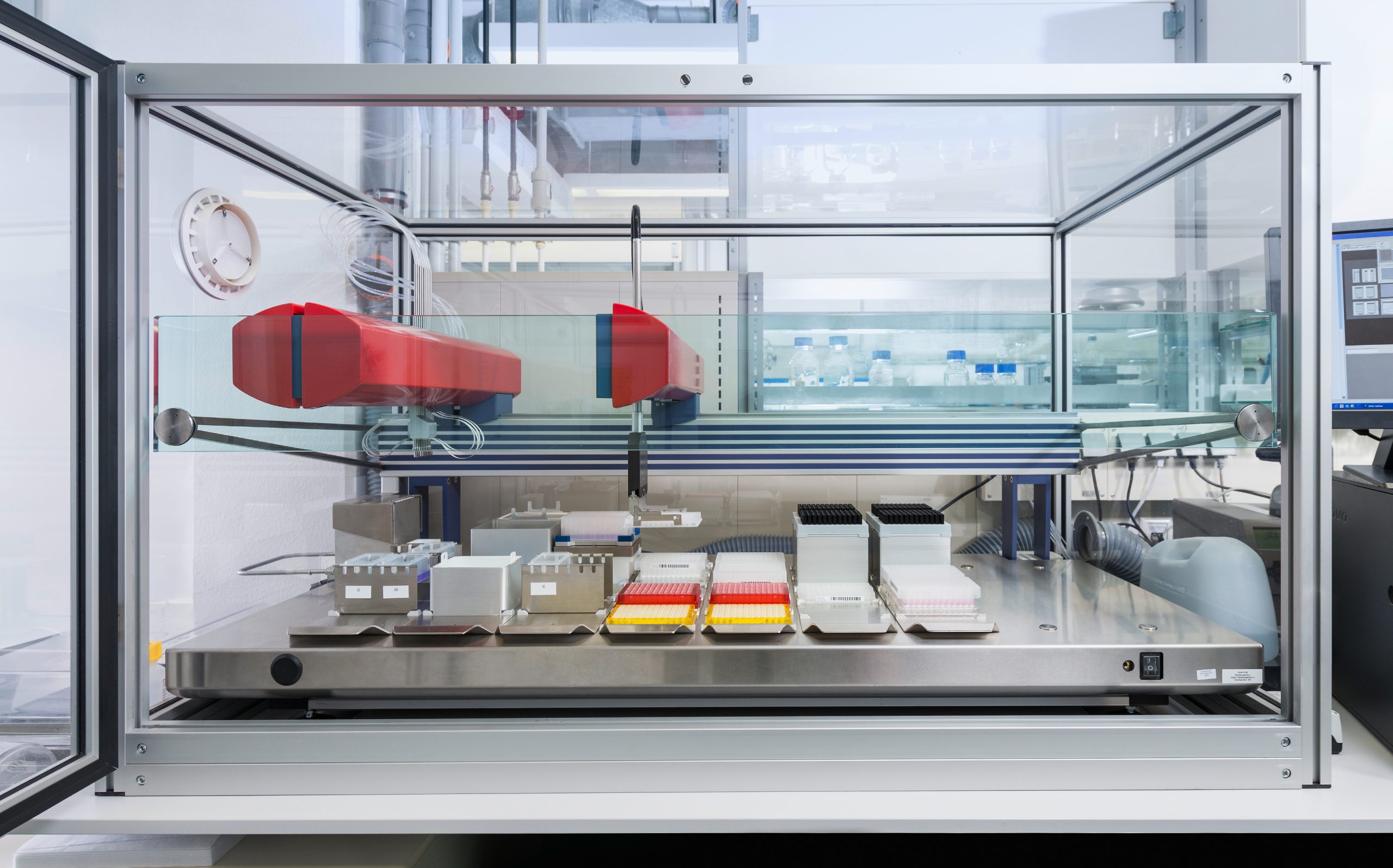

At CureVac, we describe our production philosophy as “biopharma meets IT.” Much like a programmer will write a code that carries instructions to a computer, during our R&D process, we use mRNA sequences to “write” a new “code” that will be translated by the body to the corresponding protein. This process means we have the possibility to use the same, standardized process to produce all of our mRNA therapeutics.

Where the science happens

CureVac has developed the entire, end-to-end manufacturing process itself and has extensive intellectual property covering its production techniques and technologies. We manufacture our mRNA therapeutics in our own GMP-compliant plants, which are 100% dedicated to producing high-quality mRNA molecules for biomedicine—including the world’s first. Our production plants are:

GMP certified

Our plants have been inspected by competent authorities and authorized for production of clinical trial material.

Reproducible

One production facility can be used for mRNA products with different sequences and is a template for additional facilities.

Standardized

Production process for all mRNA constructs is standardized across plants.

Flexible

Quickly able to switch to production of new products.

Scalable

Scale-up for industrial manufacturing possible.

Our GMP-compliant facilities

Meet The RNA Printer®: our mobile production facility

No longer will mRNA therapeutic production be limited by large facility production. We are continuing to develop a portable mRNA “printing” facility – we call it The RNA Printer®. The RNA Printer® assists with a rapid response to outbreaks and can be stationed in hospitals to provide personalized medicine.